Metal Fabrication Services

Introducing Advanced Robotic Welding Services

Lee Metal Fabrication is proud to announce the addition of the Fusion Arc 180 automated welder to our fabrication services. This cutting-edge robotic welding system brings unparalleled precision, consistency, and speed to every project, ensuring high-quality results that set us apart.

Our automated welding services are designed to enhance productivity, improve precision, and offer cost-effective solutions for a variety of industries and applications.

Benefits of Automated Welding

Automated welding offers numerous advantages that elevate your projects with quality and efficiency:

Increased EfficiencyAutomated systems significantly boost production rates compared to manual welding, reducing lead times and ensuring timely project delivery.

Superior QualityThe Fusion Arc 180 provides...

Read The Rest

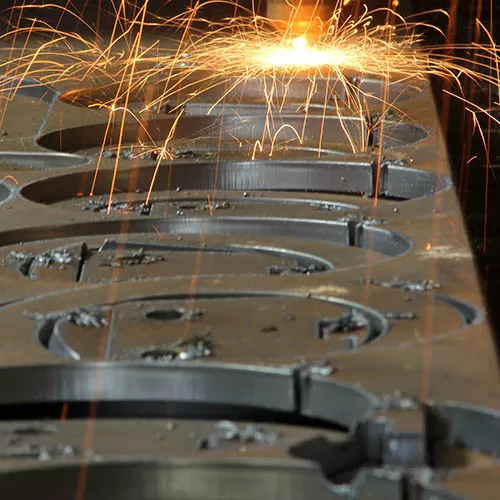

Rapid Commercial Laser Cutting

Our flat laser cutting systems at Lee Metal Fabrication allow for fully automated, lights-out production of all sorts of material thicknesses and types including aluminum, steel, high-hardness steel and many other metals and alloys. We combine the use of our high-end equipment with decades of laser cutting expertise, design and engineering.

When your metal fabrication project requires small or large quantities of accurately finished parts, flat sheet laser cutting from Lee Metal Fabrication is the answer. Used to cut sheet metal accurately, flat sheet laser cutting employs a focused laser beam that meets and then melts sheet metal, allowing for super...

Read The Rest

Tube & Pipe Laser-Cutting

Lee Metal Fabrication's tube laser cutting machines will cut tube, channel or structural shapes to length while also adding holes or complex cutout designs - all in a single step. From a simple mounting hole to an ornate architectural detail, precision is everything. Our laser cutting technology produces precise and complex laser cut geometry on angle, box, channel, pipe, and tube materials.

Laser tube cutting is the way to go when you want high-quality cuts and designs ready for assembly and construction. For strong, crisp cuts that need no extra work, a laser tube cutter should be your choice. Laser tube...

Read The Rest

Bending Sheet & Plate Metal

A CNC press brake is a machine tool for bending sheet and plate material, most commonly sheet metal. With the use of CNC press brake machines, Lee Metal Fabrication can create precise bends in sheet metal and wire forms. This allows Lee Metal Fabrication to create perfectly shaped objects out of sheet metal.

In wire products, the CNC press brake machine allows for perfectly uniform bends in a series of parallel wires along an edge. Combined with laser cutting, Lee Metal Fabrication can make many small, intricate housings for sensitive parts using CNC press brake technology. Our CNC press brake machines...

Read The Rest

Superior Cut Quality and Consistency

Lee Metal Fabrication's high definition plasma-cutting services are a reliable alternative to other traditional metal cutting services where accurate angles and precision cutting is crucial. Our plasma cutting units consistently produce high-quality, cut-in materials of varied thickness and length. Some of the benefits of CNC-controlled, plasma cutting include optimal cutting, guaranteed consistent performance, and high accuracy or precision cuts.

Highly accurate

Excellent edge finishes

Stainless steel, aluminum, copper and carbon steel

Superior cut quality and consistency

Efficient and cost-effective part production

Fast turnarounds

Compatible with any CAD/CAM/digital design files

High precision and perfect repeatability

Lee Metal Fabrication offers high def plasma cutting with capabilities of cutting up to 2"...

Read The Rest

Efficient, Versatile, and Consistent Machining

Lee Metal Fabrication provides the best in CNC lathe machining and turning services. Equipped with highly skilled CNC programmers and machinists, as well as horizontal and vertical turning centers, we consistently exceed our clients’ precision, accuracy, and quality standards.

If you have complex components with tight tolerance, high precision demands, Lee Metal Fabrication has the equipment, knowledge, and experience to meet your exact specifications. Quick-turn CNC machining works best for prototyping, form and fit testing, jigs and fixtures, and functional components for end-use applications.

CNC Lathe Turning

Lee Metal Fabrication has two Haas ST-30 CNC lathes to handle all of your turning needs.

The...

Read The Rest

Accurate Metal Sawing Cutting Services

Lee Metal Fabrication's saw cutting services provides quality and precision for your saw cutting needs. With the Marvel 380A Automatic Vertical Band Saw, Lee Metal Fabrication can handle a diverse amount of materials. Capable of cutting opposing, and parallel miters up to 60 degrees with automation. Our vertical band saw is great for square bar, round bar, flat bar, angle, channel, square tubing and pipe.

Lee Metal Fabrication offers stainless steel saw cutting services using our fully automatic saws that can cut your material to your required size. With up to 16” capacity, we can handle all your bar, tube, and pipe...

Read The Rest

Metal Forming and Rolling

Lee Metal Fabrication's forming and rolling operations are part of a complete line of advanced metal manufacturing services that meet high industry standards and diverse requirements. Lee Metal Fabrication provides solutions for bending, folding, forming, notching, punching and shearing and cut to length services.

Our versatility, quality manufacturing, and customer focus is why our customers come back to us project after project. From concept to finished product, our expertise in design engineering, machining, fabrication, and assembly will ensure your project requirements are met on time and on budget.

Our well-equipped facility has the capabilities to bend, shear, notch, punch, saw, drill, angle, or plate roll, weld, braze, and plasma burn small, large and heavy...

Read The Rest

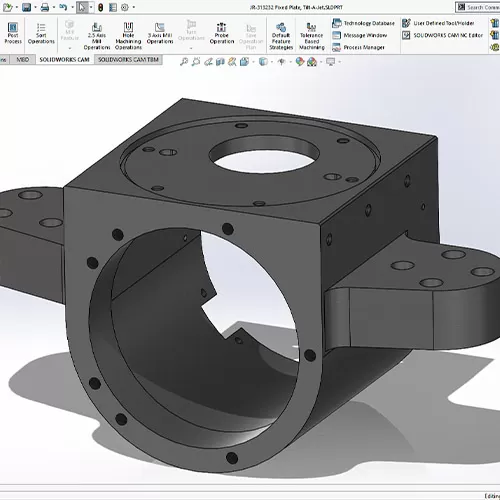

We Can Read Your Files and Drawings

Lee Metal Fabrication has a wide variety of software tools to help us in your design. Whether you have simple DFX files to very large 3-D Models, we have the software to accommodate your needs. We can also take a simple sketch or blue printed drawings and turn them into computerized files.

To draw parts on the computer for our clients, we can work from a drawing off the back of a napkin or a mock-up of parts prepared in a file type we can read, such as JPG, GIF, BMP, or PDF.

The CNC Programmers at Lee Metal Fabrication can handle...

Read The Rest